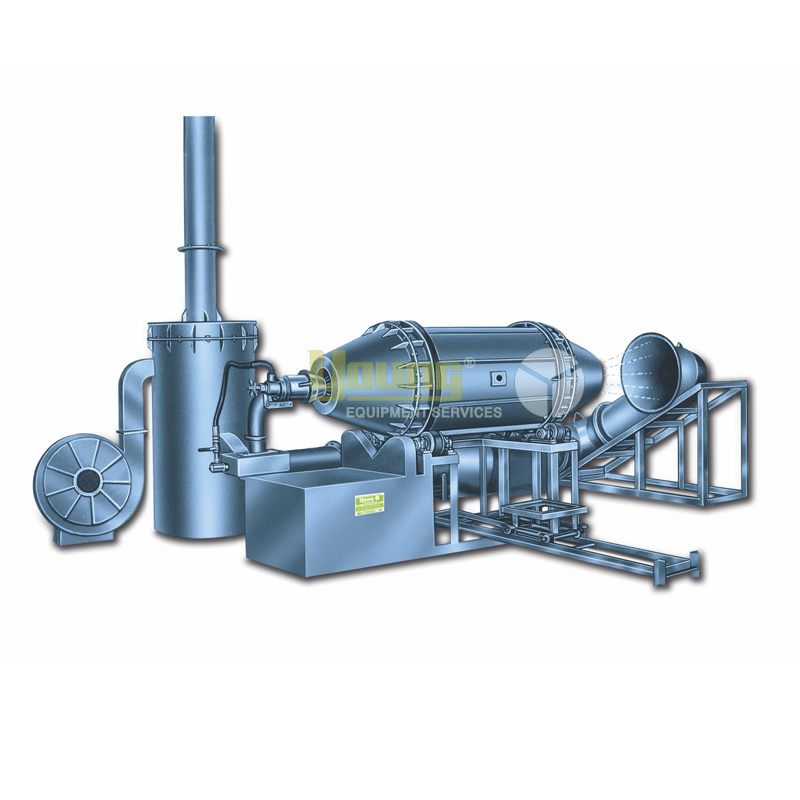

Rotary Oil Fired Furnace

Rotary Oil Fired Furnace: "YES" offers an efficient & ideal new design unit for high temp. and low fuel cost for melting C.I. Alloy. Ferrous & non Ferrous metals. Simpalicity of operation & high thermal efficiency.

The shell is fabricated robustly from M.S. Plates & remaining other parts from heavy gauge sheets. The centre portion is cylindrical & the ends are conical. Two M.S. Tyres are provided on the shell rotation. The base frame structure is robustly fabricated for continuous heavy & hard use. The drive support and guide rollers are off cast iron . The roller shafts are mounted on heavy duty bearings coupled pedestals. The burning system consists of a high capacity & efficient burner. An efficient new design steel tube recuperate and burner is used to preheat the air more. Result in fuel saving & also ensures quicker melts.

Rapid Melting, Intimate Mixing, Flexibility of production, lower Melting Cost. Refractory, Electric & pipe Fitting are not supply with furnace.On Complition of Erection Giving A Complete Satisfactory Trial.

The furnace is supplyed complete with following units...

- 1. Frame with rollers running on bearing coupled pedestals.

- 2. Reduction gear with Electric motor for shell driven.

- 3. Motorised air Blower.

- 4. Draught chamber

- 5. Exaust bends

- 6. Recuperator

- 7. Shell Nos.

- 8. Chimney

- 9. Oil tank

- 10. Ladles

- 11. Burner

- 12. Trolley

- 13. Rail

| Melting Capacity (apprx.) | Melting Time minutes (apprx.) | Heating Time Minutes | H.P. of Ele. Motor | Ground Area Required L x W | |

| Shell H.P. | Blower H.P. | ||||

| 25 Kg | 12 | 10 | 0.5 | 2.0 | 15' x 12' |

| 50 Kg | 16 | 10 | 0.5 | 3.0 | 15' x 12' |

| 100 Kg | 20 | 10 | 1.0 | 5.0 | 18' x 12' |

| 150 Kg | 25 | 15 | 1.0 | 5.0 | 18' x 12' |

| 250 Kg | 35 | 15 | 1.0 | 7.5 | 22' x 15' |

| 400 Kg | 45 | 15 | 2.0 | 7.5 | 22' x 15' |

| 500 Kg | 55 | 15 | 2.0 | 10.0 | 25' x 15' |

| 750 Kg | 70 | 15 | 2.0 | 12.5 | 25' x 18' |

| 1000 Kg | 90 | 20 | 3.0 | 15.0 | 30' x 20' |

| 2000 Kg | 120 | 25 | 5.0 | 20.0 | |